Basics of Gas Chromatography

4-2 Baseline Problems

Baseline-related problems can range from column deterioration and contamination to equipment malfunctions. The baseline anomalies were divided into five categories: drift, spikes, noise, instability, and swell. Any problems related to equipment anomalies should be checked in the instruction manual of the equipment.

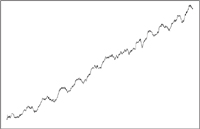

Drift

|

Main Causes

|

Approach

|

|

Insufficient column conditioning

|

Condition the column as described in Handling of Capillary Columns.

|

|

Air (water, oxygen) contamination

|

If excessive drift (baseline rise due to liquid phase stripping) occurs, check the carrier gas.

|

|

Degradation of column (liquid phase)

|

Replace the column.

|

|

Insufficient detector equilibration

|

Wait until the detector stabilizes.

|

|

Detector contamination

|

Clean the detector.

|

Spikes

|

Main Causes

|

Approach

|

|

Insufficient column connection

(detector side) |

This may occur when the column is inserted too far.

Check that the column insertion length matches the position specified in the instruction manual of the GC system. |

|

Detector contamination

|

Clean the detector.

|

|

Defective signal cable

|

Check for contact defects or insulation defects. Replace the cable if necessary.

|

|

Faulty electrical cable or power supply

|

Provide a stable power supply.

|

Noise

|

Main Causes

|

Approach

|

|

Detector contamination

|

Clean the detector.

|

|

Contamination of column (liquid phase)

|

Condition the columns. Cut approximately 50 cm off the inlet side of the column. If there is no improvement, replace the column.

|

|

Inlet contamination

|

This may be caused by liner contamination from inlet septum debris or sample residue. Clean or replace the liner. Replace the inlet septum.

|

|

Improper column connection (detector side)

|

The column might be inserted too far. Adjust the column insertion length to the position specified in the instruction manual of the GC system.

|

|

Inadequate carrier gas flow rate

|

Set the flow rate as specified in the instruction manual of the GC system.

|

|

Carrier gas leak (in MS, TCD, ECD)

|

May be caused by air leakage. Identify and remedy the leakage areas.

|

|

Detector failure

|

Replace or repair any defective filaments, electron multipliers, amplifiers, boards, etc.

|

Instability and Wander

|

Main Causes

|

Approach

|

|

Insufficient column conditioning

|

|

|

Contamination of column (liquid phase)

|

Condition the columns. Cut approximately 50 cm off the inlet side of the column. If there is no improvement, replace the column. |

|

Inlet contamination

|

This may be caused by liner contamination from inlet septum debris or sample residue.Clean or replace the liner. Replace the inlet septum. |

|

Detector contamination

|

Clean the detector.

|

|

Detector temperature instability (of TCDs)

|

Check the temperature stability of the device.

|

|

Unstable carrier gas flow rate, insufficient purity

|

Check the flow rate and gas purity (contamination).

|

|

Inappropriate temperature environment

around the equipment |

Check the ambient temperature.

|