Basics of Gas Chromatography

2-2 Capillary Column Selection Method

This section describes the points to consider when selecting a capillary column. These points are listed below.

- Type of liquid phase

- Column Length

- Column I.D.

- Film thickness of the liquid phase

The effects of each factor on the actual analysis are described below.

2-2-1 Types of Liquid Phases

| Description | Liquid Phase | USP Code | Polarity | Application |

|---|---|---|---|---|

| InertCap 1MS | 100% Dimethylpolysiloxane | G1, G2, G38 | None | General Analysis, Hydrocarbon, High Boiling Components, PCB, Phenol |

| InertCap 1 | 100% Dimethylpolysiloxane | G1, G2, G38 | None | General Analysis, Hydrocarbon, High Boiling Components, PCB, Phenol |

| InertCap 1HT | 100% Dimethylpolysiloxane | G1, G2, G38 | None | High Boiling Petroleum Products, Diesel Fuel, Long-chained Hydrocarbons, Motor Oils, Polymers |

| InertCap 5MS/Sil | 5% Diphenyl(equiv.)- Dimethylpolysilphenylene siloxane |

G27, G36 | Low | General Analysis, Halogen Compound, Phenol, Pesticides, FAME |

| InertCap 5MS | 5% Diphenyl 95% Dimethylpolysiloxane |

G27, G36 | Low | General Analysis, Halogen Compound, Phenol, Pesticides, FAME |

| InertCap 5 | 5% Diphenyl 95% Dimethylpolysiloxane |

G27, G36 | Low | General Analysis, Halogen Compound, Phenol, Pesticides, FAME |

| InertCap 5HT | 5% Diphenyl(equiv.)- Dimethylpolysilphenylene siloxane |

G27, G36 | Low | High Boiling Petroleum Products, Diesel Fuel, Long-chained Hydrocarbons, Motor Oils, Polymers |

| InertCap Pesticides | 5% Diphenyl(equiv.) Dimethylpolysilphenylene siloxane |

G27 | Low | Screening Analysis of Multiresidue Pesticides |

| InertCap 624MS | 6% Cyanopropylphenyl 94% Dimethylpolysiloxane |

G43 | Middle | Residual solvents of Pharmaceuticals, VOCs, Alcohols |

| InertCap 624 | 6% Cyanopropylphenyl 94% Dimethylpolysiloxane |

G43 | Middle | VOC, Alcohol |

| InertCap 1301 | 6% Cyanopropylphenyl 94% Dimethylpolysiloxane |

G43 | Middle | Pesticides, PCB, Alcohol, VOC |

| InertCap 25 | 25% Diphenyl 75% Dimethylpolysiloxane |

G28 | Middle | Pesticides, PCB, Alcohol, VOC |

| InertCap 35MS | 35% Diphenyl 65% Dimethylpolysiloxane |

G42 | Middle | Pesticides, Pharmaceuticals, Polycyclic aromatics |

| InertCap 35 | 35% Diphenyl 65% Dimethylpolysiloxane |

G42 | Middle | Pesticides, Pharmaceuticals |

| InertCap 1701MS | 14% Cyanopropylphenyl 86% Dimethylpolysiloxane |

G46 | Middle | Pesticides, Sugar, TMS derivatives, Drugs, Alcohol, Steroids |

| InertCap 1701 | 14% Cyanopropylphenyl 86% Dimethylpolysiloxane |

G46 | Middle | Pesticides, Sugar, TMS derivatives, Drugs, Alcohol, Steroids |

| InertCap 17MS | 50% Diphenyl 50% Dimethylpolysiloxane |

G3 | Middle | Steroid, Drug, Pesticides |

| InertCap 17 | 50% Diphenyl 50% Dimethylpolysiloxane |

G3 | Middle | Steroid, Drug, Pesticides |

| InertCap 210 | 50% Trifluoropropyl 50% Methylpolysiloxane |

G6 | Middle | Organophosphorus Pesticides |

| InertCap 225 | 50% Cyanopropylmethyl 50% Phenylmethylpolysiloxane |

G19 | Middle - High | FAME |

| InertCap Pure-WAX | Polyethylene Glycol | G16 | High | General Analysis, Ester, Flavor, Alcohol, Aromatic, FAME |

| InertCap WAX | Polyethylene Glycol | G16 | high | General Analysis, Ester, Flavor, Alcohol, Aromatic, FAME |

| InertCap WAX-HT | Polyethylene Glycol | G16 | High | General Analysis, Ester, Flavor, Alcohol, Aromatic, FAME |

| InertCap FFAP | Nitroterephthalic acid modified Polyethylene Glycol |

G35 | High | FAME, Free Fatty Acid, Organic Acid, Alcohol, Aldehyde |

If the above columns (liquid phase) are unsuitable for the analysis or the analytical conditions should be further optimized, a dedicated column should be used.

Specific Columns

| Description | Liquid Phase | USP Code | Polarity | Application |

|---|---|---|---|---|

| InertCap for Amines | Special liquid phase | - | Amine Compound, Alcohol | |

| InertCap CHIRAMIX | Special liquid phase | - | Optical Isomer | |

| InertCap AQUATIC | 25% Diphenyl 75%Methylpolysiloxane |

G28 | Middle | VOC, Organic Solvent |

| InertCap AQUATIC-2 | 25% Diphenyl 75%Methylpolysiloxanee |

G28 | Middle | VOC, Organic Solvent |

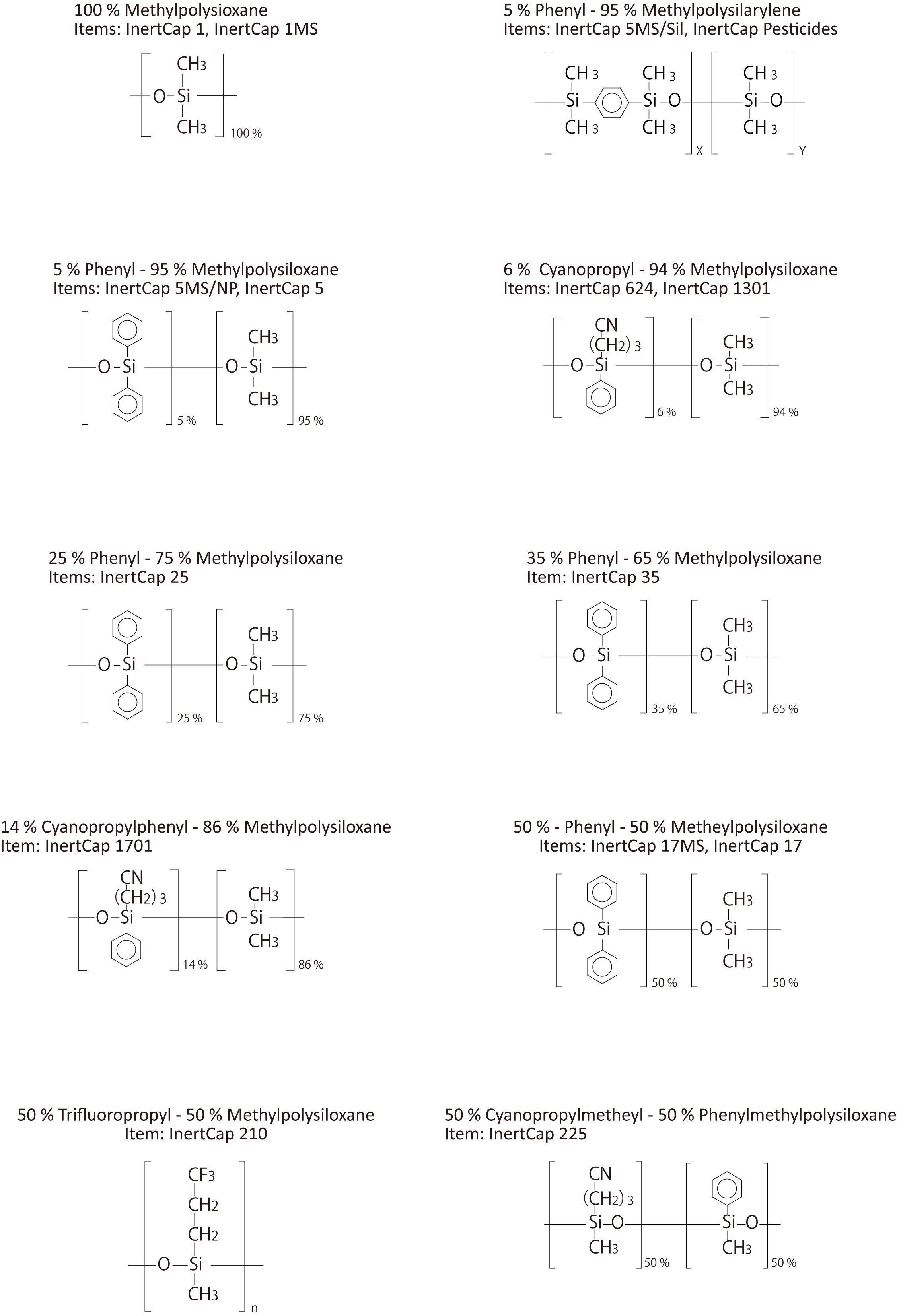

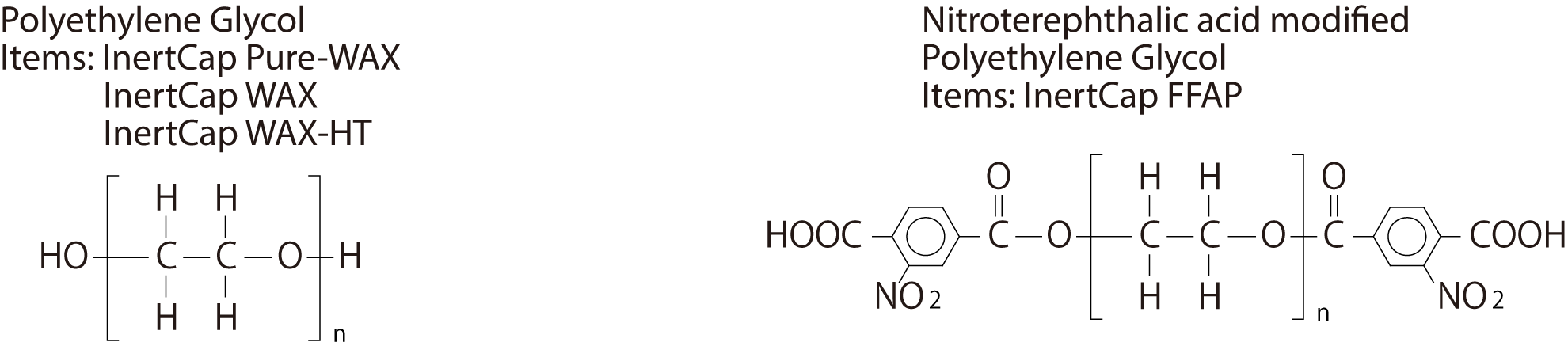

Liquid phases for general analyses are structurally divisible into silicon-based liquid phases and WAX-based liquid phases. Silicon-based liquid phases are characterized by the presence of methyl, phenyl, cyanopropyl, and other groups on the side chains of the Si–O–Si basic skeleton. Those with methyl groups on all side chains (called nonpolar liquid phases) are the least polar among all silicone-based liquid phases. Polar liquid phases are generated by replacing the methyl group by a phenyl or cyanopropyl group. The polarity of the liquid phase strengthens with increasing ratio of the polar group. The WAX-based liquid phase is highly polar and its basic backbone is a polymer of ethylene glycol. Free fatty acid phase (FFAP), a polymer of polyethylene glycol and nitro terephthalate, is even more polar and is used in analyses of free fatty acids and fatty acid esters.

Structural Formula of Silicon-Based Liquid Phase

Structural Formula of WAX-Based Liquid Phase

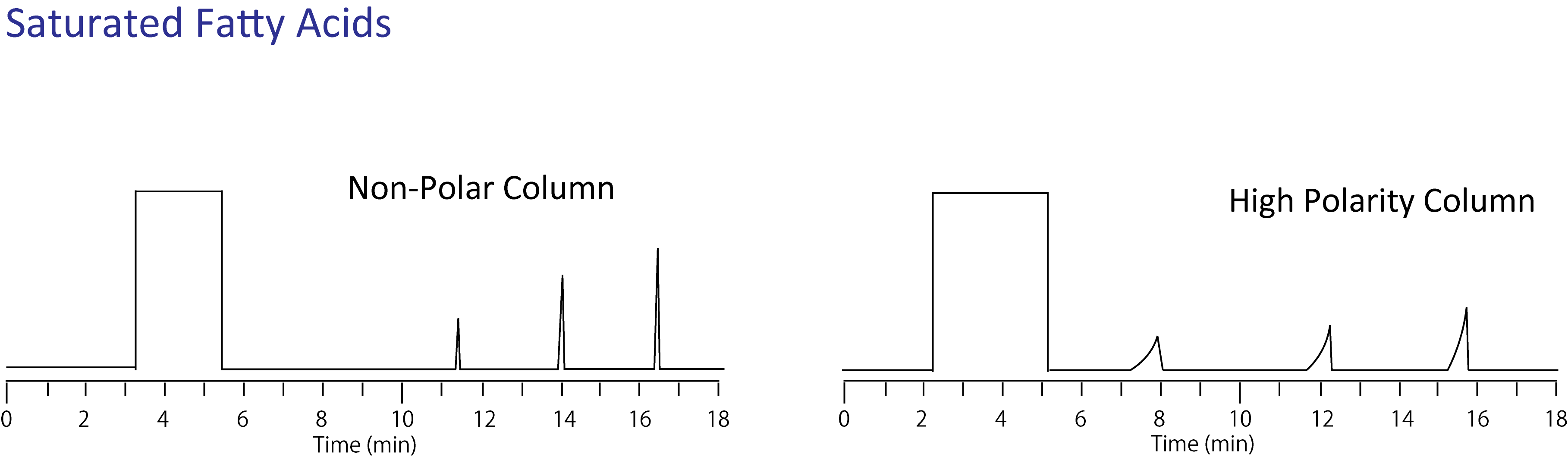

When selecting a liquid phase column, you must first match the polarities of the analyte and the liquid phase of the column. For example, if you are measuring polar substances such as alcohols or fatty acids, you should choose a WAX-based column or a highly polar FFAP column. If the polarity of the substance to be measured differs from that of the column, the solubility of the substance in the liquid phase might be reduced and the peak shape can be degraded. In addition, the sample load cannot be increased because an increased load reduces the allowable sample volume of the liquid phase. Below is an example of fatty acids measured on a nonpolar column and a highly polar column. The nonpolar column yielded poor peak shapes for the lower-molecular-weight fatty acids, whereas the highly polar column produced reasonable results. In the liquid phase of the highly polar column, the fatty acids spent more time dissolved in the liquid phase, causing stronger retention and slower elution times.

Comparison of Chromatograms from Different Liquid Phases

2-2-2 Column Length

The column length affects the theoretical plates and the analysis time. The lengths of commercial capillary columns range from 5–100 m, among which 30–60 m columns are commonly used. Doubling the length doubles the theoretical plates and the analysis time, but the separation improvement factor (~1.4) may be lower than expected. Longer columns are recommended for separation purposes whereas shorter columns are recommended for fast analyses. The selected column should be the shortest column that maintains the separation performance.

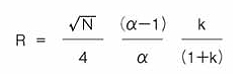

Deployment of Separation

R: resolution

N: number of theoreticalplates

α: separation factor

k: retention factor

2-2-3 Column I.D.

The inner diameter of the column affects the theoretical number of stages, degree of separation, and sample loading. In typical applications, the inner diameter is 0.25–0.53 mm. Columns with narrower inner diameters have a higher theoretical number of stages per unit length than wider columns, so are recommended when separation is important. However, narrow columns require enlargement of the split ratio or other adjustments to the introduction volume to compensate the small sample load. For trace analysis, narrow columns may be unsuitable and a column with a larger inner diameter (0.53 mm) and a small split ratio is recommended. Columns with narrow inner diameters (0.1–0.18 mm) are also suitable for fast analysis because their high resolution increases the linear velocity.

2-2-4 Film Thickness of the Liquid Phase

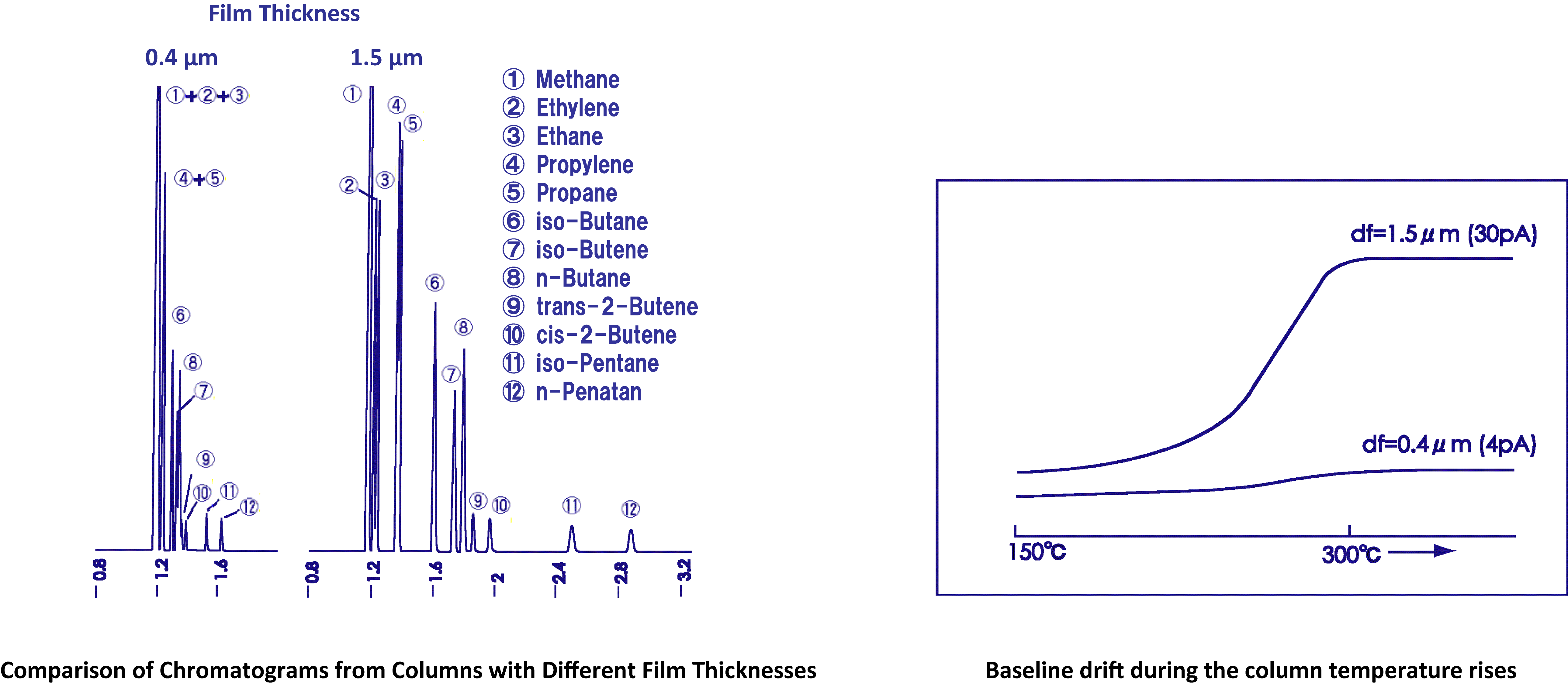

The thickness of the liquid phase film affects the analysis time and sample loading. A thick film allows higher sample loading and measurement of higher concentration samples than thin films. The chromatogram below shows how the separation improves on a thick film. In the column with 1.5 µm thick film, components other than propylene and propane were mostly separated. The retention ratio of each sample increased almost proportionally to the film thickness, lengthening the analysis time and widening the peak widths. When separating substances with high-boiling points, these broad peaks offset the separation benefits of increasing the film thickness. Moreover, thicker films are associated with larger baseline drift during programable temperature analyses.

2-2-5 Summary

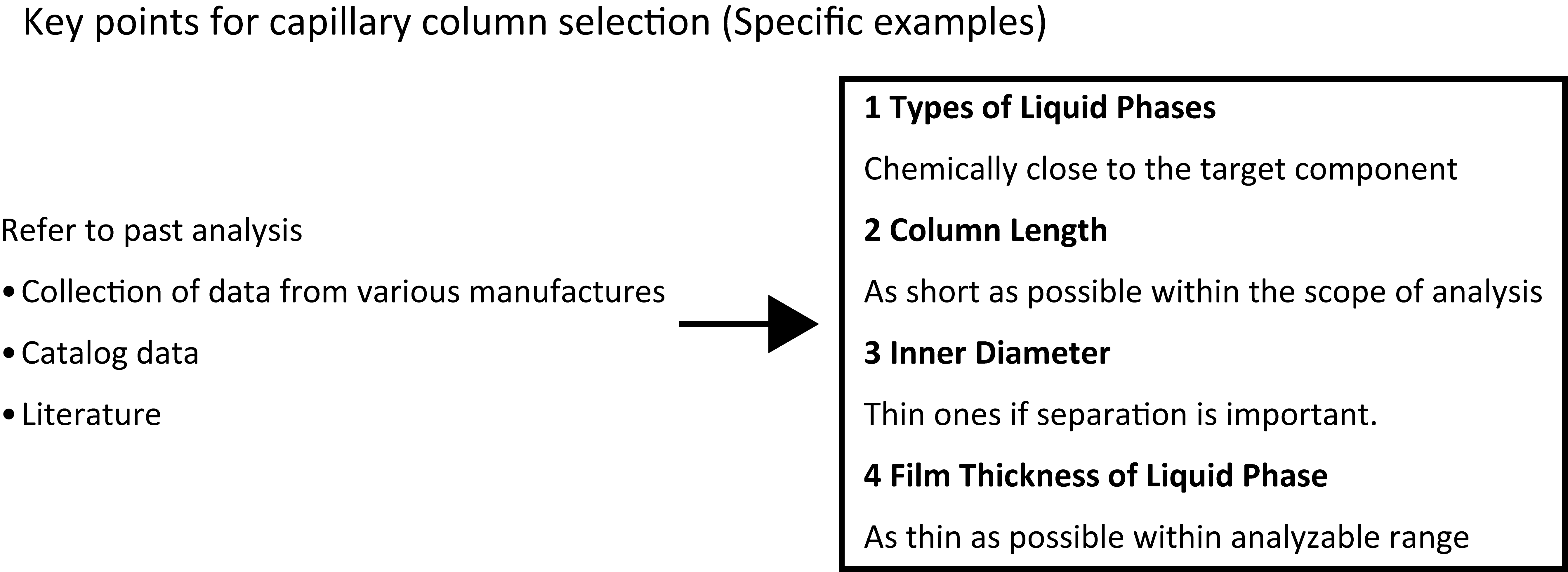

We have discussed four factors that influence capillary column selection (liquid phase, length, internal diameter, and film thickness) and their effects on the analysis. Some more specialized options are mentioned below.

To find a specific column for a particular application, seek examples of previous analyses. If you find an example that matches your objective, you should be able to obtain a similar chromatogram under the analytical conditions described therein. If no analytical examples are found, the column should be selected after considering the four factors mentioned above. Next, the selected liquid phase should be chemically close to the target component. In many cases, either InertCap 1 or InertCap WAX will be a suitable choice. The length should be as short as possible without compromising the separation (a length around 30 m is usually recommended). The inner diameter should be 0.25 mm when separation is important and 0.53 mm when large amounts of sample are injected. The film should be as thin as possible within the analyzable range (a 0.25-µm-thick film is standard).